Vaasa important for Wärtsilä’s sustainability efforts

The switch from road haulage to water-borne transport gave Wärtsilä environmental benefits and major savings. But it wasn’t all plain sailing.

WÄRTSILÄ - THE FINNISH TECHNOLOGY COMPANY - is building a large research, development and production plant in Vaasa. The facility, known as the Smart Technology Hub (STH), is scheduled for completion in 2021.

Financially and environmentally unsustainable

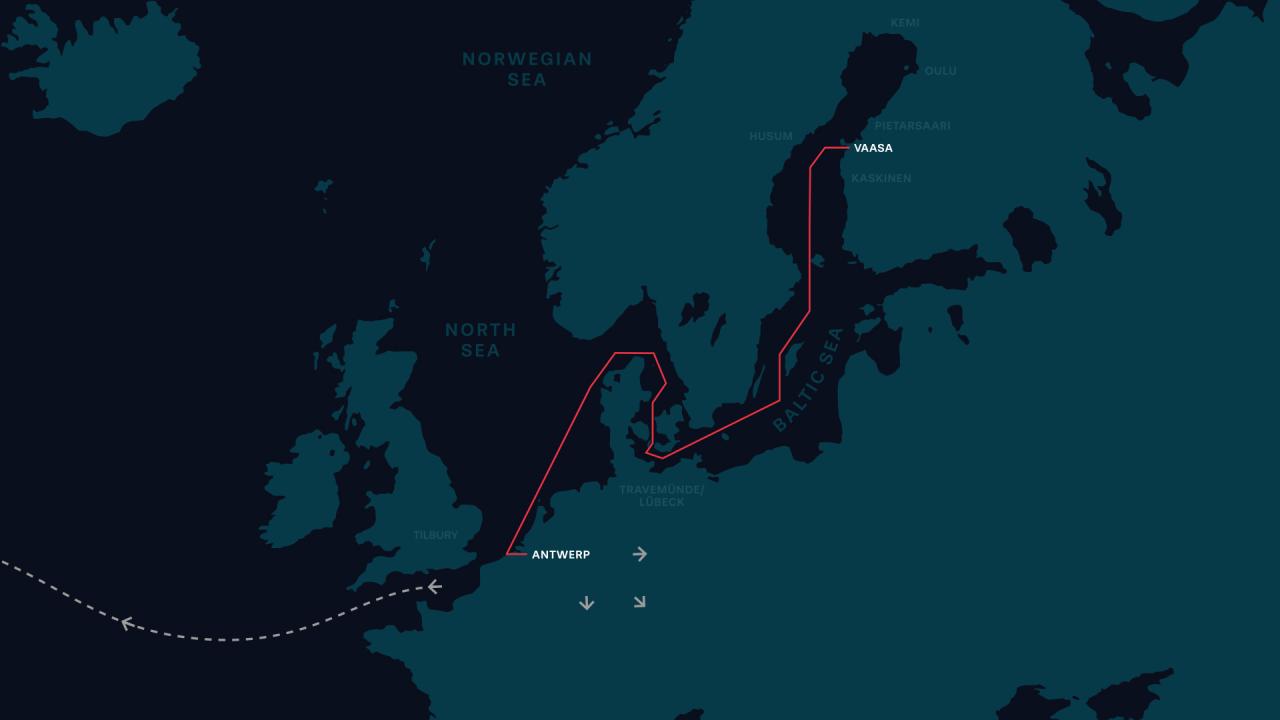

Wärtsilä reviewed its processes in connection with STH, including logistics. The company purchases materials from central Europe and transports them to the factory in Vaasa. Like most other Finnish companies, Wärtsilä previously hauled the goods to northern Germany by trailer. From there, it was shipped across the Baltic Sea to ports in southern Finland for onward transport (200–300 km) by road to Vaasa.

“Because road haulage is a poor choice in terms of both the environment and economics, we investigated the possibility of shipping the goods directly to the Port of Vaasa,” says Mikael Lindberg, Development Manager, Wärtsilä.

Information flows and fluctuating exports

The company had previously considered the port solution in Vaasa. The problem at the time was that Wärtsilä’s exports fluctuated too much to make the deal worthwhile.

“This time we turned things upside down and looked at constant input volumes. Building on these volumes, we began discussions with WALLENIUS SOL. Because they also had other flows, Vaasa was a port with good investment potential for both of us,” says Mikael Lindberg.

However, the process of redirecting flows was not entirely painless. Since the new port solution in Vaasa involved many parties, the biggest challenge was the flow of information.

Today, Wärtsilä has a free carrier solution, i.e. it controls the entire chain and pays for the shipment from the time the supplier loads the goods until they are unloaded at Wärtsilä.

When a booking is made, it is passed to a control tower that coordinates all shipments. The information is then passed to the ports of departure and arrival. Integration of the various parties’ systems and the related negotiations took around one year.

Environmental benefits and major savings

The Port of Vaasa is now linked to WALLENIUS SOL’s Baltic Sea infrastructure. Incoming loads are coordinated at a hub in Antwerp and then taken to Vaasa on scheduled services. Wärtsilä’s completed engines are shipped out on the return trips.

“It’s particularly pleasing that other companies see the benefits this new transport solution brings. It’s not surprising. Switching shipments away from road haulage to the Baltic has not only made shipping cheaper, but has also reduced CO2 emissions,” says Mikael Lindberg.

He adds:

“Since we consolidate loads ourselves, we have more goods per transported unit. I won’t hazard a guess as to precisely how much lower CO2 emissions the port solution achieves, but it’s at least 10 per cent. It forms an important part of our sustainability efforts.”