Environmental gains just around the corner

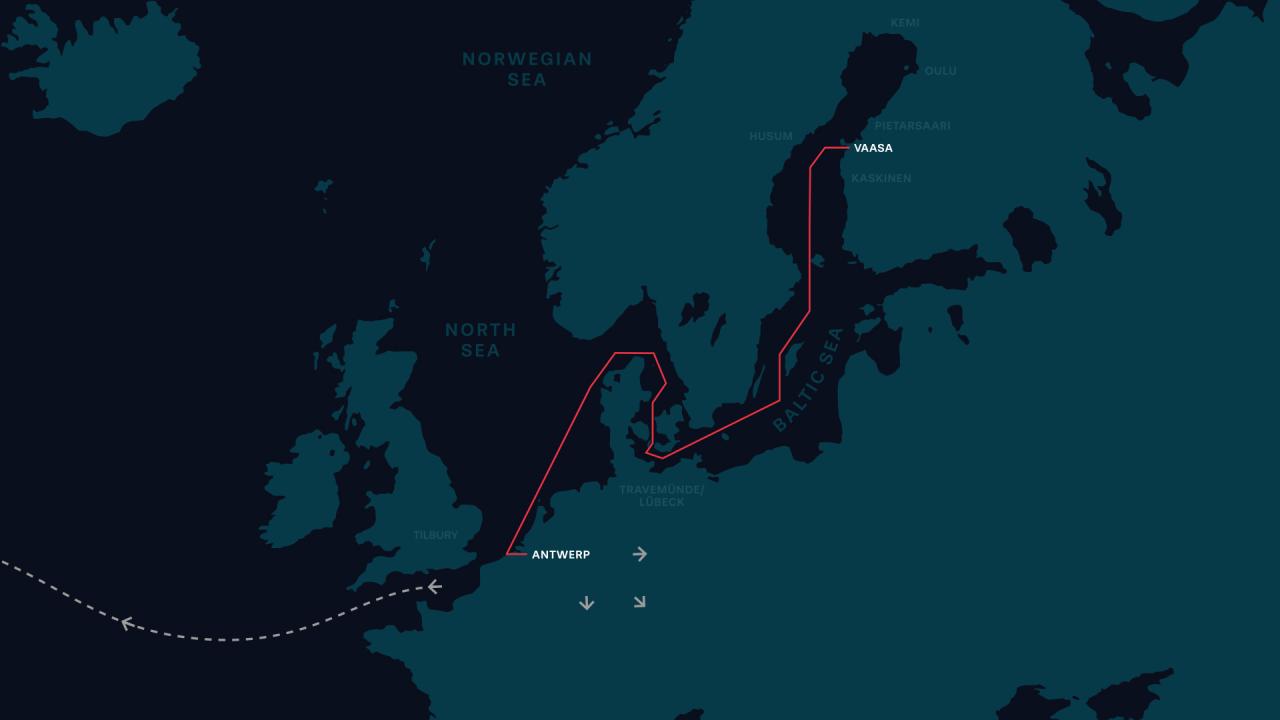

Even though the paper mill is located less than 1 kilometre from the harbour, BillerudKorsnäs was forced to ship its goods by rail to another port more than 330 kilometres from the mill. Their collaboration with WALLENIUS SOL has saved them both time and money and provided major environmental benefits.

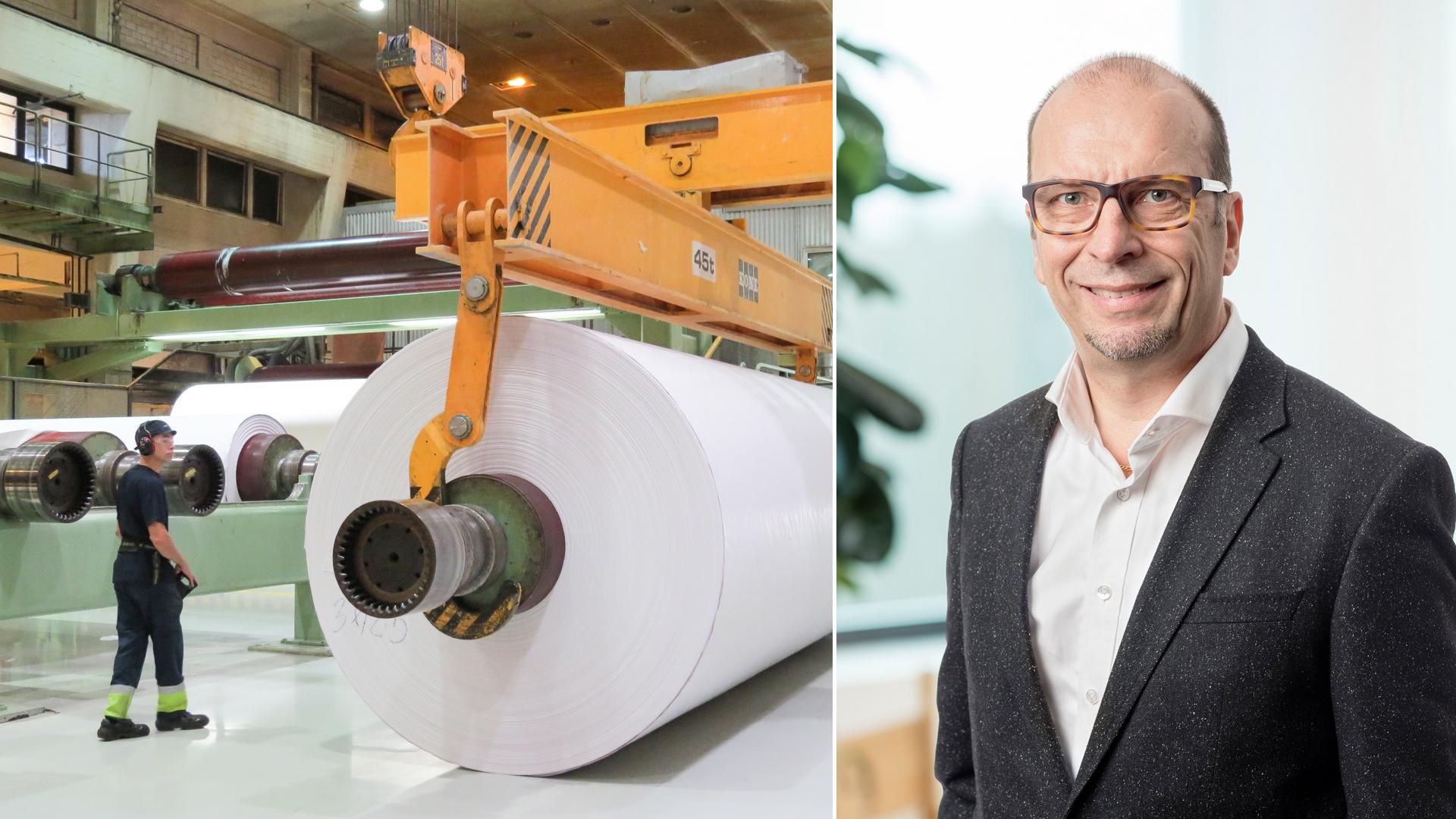

A RESPONSIBLE, SUSTAINABLE value chain forms an important part of BillerudKorsnäs sustainability efforts. The company has production facilities in Sweden, Finland and England, and ships most of its goods by rail through its own rail company, Scanfiberlogistics. But in the case of shipments from Finland, other solutions are necessary.

“Finland is a logistical island. It uses an entirely different railway gauge than the rest of Europe, so maritime shipping is the only solution for us,” explains Risto Hovi, Managing Director of BillerudKorsnäs Finland.

But even though the paper mill is but a stone’s throw from the harbour, up until 2019 there was no other solution than shipping the goods by rail or road to Rauma, just over 330 km south of Pietarsaari, before transfer to a shipping line and ships bound for Germany, Belgium or England.

“We saw the need for a logistics set-up based on maritime shipping direct from Pietarsaari. We needed a partner who was able to negotiate the harbour with a RoRo vessel, and run a weekly service from Pietarsaari to Lübeck, Germany. This was where WALLENIUS SOL came into the picture,” says logistics manager Peter Löfgren.

For many years, WALLENIUS SOL had shipped products from the northernmost BillerudKorsnäs paper mill in Karlsborg, Sweden, from the Port of Kemi in northern Finland. A little over two years ago, the dream shared by the two companies was fulfilled when a new service from Pietarsaari on the route between Kemi and Lübeck was inaugurated. For BillerudKorsnäs, this means both its paper mills can use the same logistics set-up.

“Because our customers have goods from both Pietarsaari and Karlsborg, getting everything delivered to the same terminal is an advantage for them. For our part, we gain both financially and in terms of quality as instead of having to transfer the goods in Rauma, the cassette is now loaded at the mill and shipped without interruption all the way to the terminal,” says Peter Löfgren

Risto Hovi adds:

“This set-up simplifies the entire process; it frees up time for our delivery planners and aligns perfectly with our ambitious sustainability goals.”

For BillerudKorsnäs, the new logistics set-up means environmental gains of around 137,000 kg carbon dioxide emissions per year as they’ve been able to avoid unnecessary preliminary shipping by road and rail.

“We’re continuing to study how to make even better use of the maritime solution, and we recently transferred a further 6,000 tonnes from land to sea. Finding sustainable solutions is very rewarding and even more so when everybody is working to achieve the same goal, as in this project,” concludes Peter Löfgren.

About BillerudKorsnäs

BillerudKorsnäs was founded in 2012 and is a world leading supplier of fresh pulp packaging material. It has customers in more than 100 countries and a total of 4,500 employees in Sweden and England.

In Addition

“Shipping right from our own doorstep is pure luxury”

In the past, shipping products from its factory to its customers in Europe was a major logistics affair for Finnish trailer and flatbed manufacturer Ekeri. But not today. Since its collaboration with WALLENIUS SOL, it now enjoys a big competitive advantage with a harbour only 20 km from the factory, according to Daniel Asplund, quality and environmental manager.

Where are Ekeri’s customers located, and how does your partnership with WALLENIUS SOL work?

We deliver around 700 brand-new trailers and flatbeds to our customers throughout the Nordics, Germany, England, the Netherlands and Eastern Europe every year. In the autumn of 2019, we began shipping our products with WALLENIUS SOL directly from the Port of Pietarsaari, and today there is one shipment per week.

What has the service from Pietarsaari meant for you?

Being able to ship right from our own doorstep instead of first transporting our trailers down to a port in southern Finland is pure luxury. And what’s more, WALLENIUS SOL’s timetable suits us down to a T. We can ship a week’s production on a Saturday and it arrives in Germany on Monday, without a single working day lost, which is a major competitive advantage for us.

Ekeri seeks to create products for a sustainable future; how important is the logistics chain?

For us, the line from Pietarsaari has also made a huge difference in terms of sustainability. We’ve reduced our carbon dioxide emissions by one tonne per trailer by not having to move them long distances by road. We value WALLENIUS SOL’s sustainability thinking and look forward to the arrival of their new vessels, which will reduce emissions further.