Cargo holds for space and flexibility

Botnia Enabler and its sister vessel, Baltic Enabler, are carefully planned, designed and constructed to optimize their cargo carrying capacities for servicing the Gulf of Bothnia.

The new WALLENIUS SOL vessels trafficking the Gulf of Bothnia are deadweight optimized for carrying heavy cargos like forest products, steel, industrial machinery, and special care has been taken to design an efficient infrastructure onboard the vessels.

ConRo vessels

“When we ordered the vessels, we said that we wanted to design a bucket that we could put under any tap there is. And this is what we have done. We have tried to make them as versatile as possible, with the ability to carry really heavy loads and project cargos,” says Ragnar Johansson, Managing Director, WALLENIUS SOL.

The result is a vessel type often called ConRo – a combination of container and RoRo, able to carry both.

“This means that we can basically carry any kind of cargo that’s out there, with the exception of liquid bulk. We mainly carry RoRo cargo, but can use the whole weather deck for containers. The combination of RoRo and feeder is much needed. Our RoRo cargo customers also have a demand for container services, so it’s a perfect match,” says Ragnar Johansson.

Flexible cargo holds

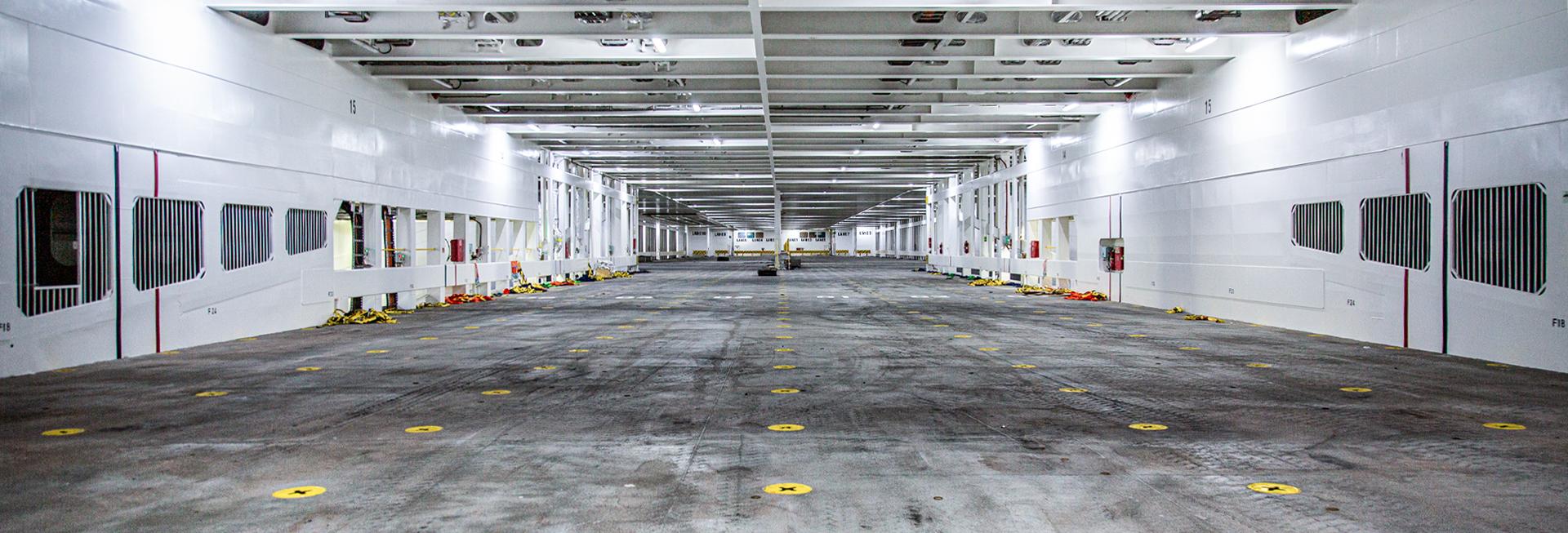

Taking Baltic Enabler as an example; she has four cargo holds: the lower hold/tank top, the main deck, the upper deck and the weather deck.

“Both the lower hold and the main deck have an internal height of 7.2 metres. This enables us to stack double containers on cassettes, and load RoRo cargos of almost any type or size. It’s really a one-of-a-kind ship,” says Mha-Ann Arguelles, Chief Officer, Baltic Enabler.

The weather deck is mostly used for carrying containers, but can be used for RoRo units thanks to the internal ramp system. The deck is covered with friction paint - paint with sand - which means that the roro cargo do not need to be lashed. The containers is locked and secured with fully automatic twistlocks, FAT. This increases the loading/unloading efficiency in port.

“The internal space in combination with enforced ramps enables us to take on large and heavy project cargos. The aft edge of the main deck can take bogie loads up to 80 tons,” says Mha-Ann Arguelles.

Three-ramp loading infrastructure

The Enabler-vessels has three separate stern ramps; center, port and starboard. Using two ramps – the center ramp and either one of the side ramps – gives simultaneous access to all cargo holds.

“We have a wider beam than most other ships. But in ports with narrower shore ramps, we can at least open two ramps. The ramps are very easy to maneuver, unlike ramps I have worked with on other vessels. We save a lot of time when we are opening or closing the ramps. Also, three ramps and several levels of cargo hold enables us to load and unload at the same time, saving more time in port,” says Mha-Ann Arguelles.

Ragnar Johansson agrees:

“We have put a lot of effort into the internal ramp system in order to load and discharge the vessels quickly while in port. Port time is money. If we can save time in port, we can go slower on the sea and burn less bunker,” he says.

Bigger is better

The new vessels are larger than their predecessors, a conscious choice.

“The newbuildings are almost twice as big as the vessels they replace, and can take three times as many containers on deck. We can load up to 97 tonnes of heavy cassettes across the whole ship. We made that decision based on a business case we worked out, which showed us that bigger vessels would be more efficient. In the future, that will turn out to be a good thing,” says Ragnar Johansson.

Baltic Enabler / Botnia Enabler

Capacity: 6,442 lane metres and 962 TEU

45’ cassette capacity: 401 cassettes

Max. free height: 7.2 metres

Deadweight (DWT): 28,000 tonnes